Follow an ALARP approach - Effort should be As Low As Reasonably Possible. Apply this to all of the aspects above, except the first.

Machine safety is primarily about sufficient risk reduction. Functionality, efficiency and cost are secondary. If you get these priorities up side down, it will result in unsafe machinery.

Never compromise safety just to save cost or increase efficiency.

Do not violate the three basic rules of machine safety!

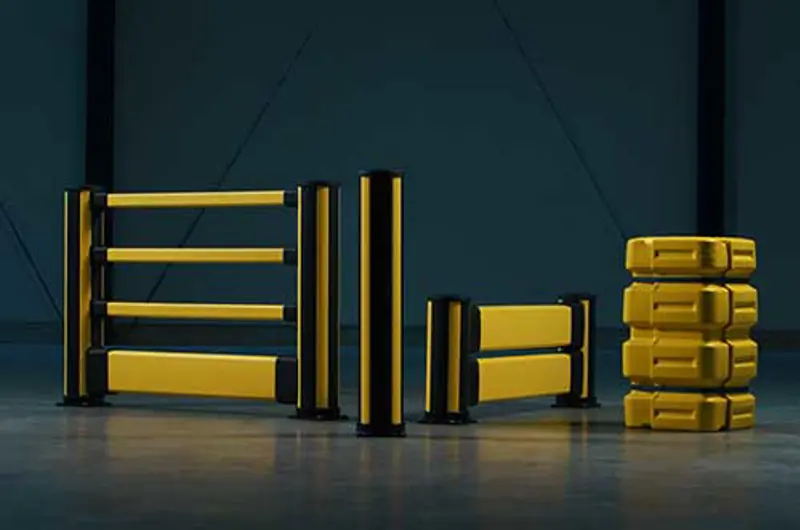

- Guarding. If there is a hazard from a moving part, hot surfaces, or electric discharge by contact, never allow people to contact the hazard involuntarily.

That is:

- Do not allow hazardous moving parts to run openly.

- Do not allow hot surfaces and live parts to be touchable.

In other words: put the lion in a cage – lock the hazard in (or people out).

- Monitoring and interlocking. If you cannot follow the first rule, monitor the time interval at which people could contact the hazard source.

End the hazard before the person can come in contact with it:

- Stop a moving part by detecting an approaching person by means of a lightbarrier, laser scanner, camera system, contact mat, ultrasound or infrared sensor etc.

In other words: put the lion to sleep with an anestetic shot, before it can eat the person.

Use sensors and the control system to monitor the presence of people or hazards (or both).

- Manual control. If you can not follow the first or the second rule, allow the person to contol the hazard. Where ever possible ensure that the person can end the hazard in time.

That is:

- Make the person press one or two buttons to start and uphold a hazardous movement or situation. Place the button(s) outside the hazard area or at a safe distance, if possible. (Two buttons: two-hand control or start button plus enabling.)

- Reduce the speed of movements so the person can still react and let go of the button(s).

In other words: make the person “tame” or remote control the lion.

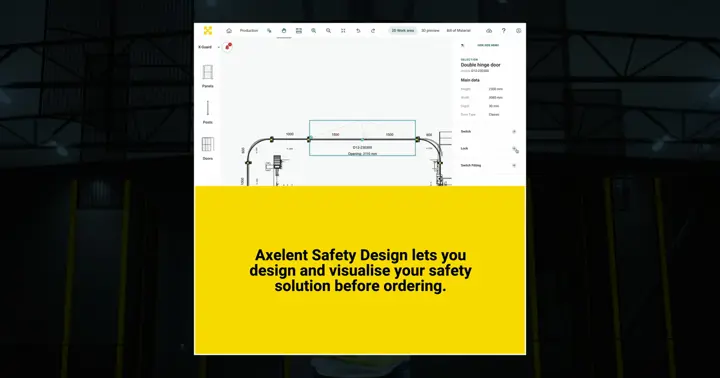

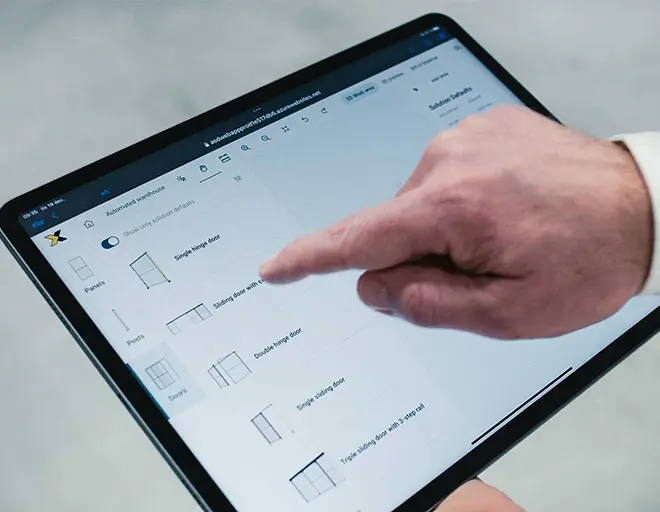

How Axelent can help you

- Safe machine design seminar

- Coaching of risk assessment and safe design on site

For more details on selecting the right safety measures read our Safety Book and the “black” chapter BASIC RULES under “Criteria for selection of guards”.

We also have a practical guide on risk assessment, that explains on just 16 pages how to identify, evaluate and reduce risks. To get the guide – Contact your local sales person.